Nhanganyaya

Munyika inomhanya-mhanya yemakomputa uye zvemagetsi zvevatengi, kudiwa kweiyo yepamusoro-chaiyo, yakavimbika, uye hunyanzvi michina yemuchina iri kuramba ichikura. Zvigadzirwa zvedu zvemuchina zvakagadzirirwa uye kugadzirwa kuti zvisangane nezvinodiwa chaizvo zveiyi indasitiri ine simba, ichiita basa rakakosha mukusimudzira mashandiro, mashandiro, uye aesthetics emhando dzakasiyana dzemagetsi.

Key Machined Zvikamu uye Mashandisirwo Azvo

Heat Sinks uye Kutonhora Solutions

■ Basa:Nekuwedzera kwesimba uye kushanda kwemakomputa processors uye zvikamu zvemagetsi, kupisa kwakanaka kwekupisa kunokosha. Masingi ekupisa anogadzirwa akagadzirirwa kukwevera kupisa kubva kune izvi zvikamu uye kuabvisa mumhepo yakatenderedza. Iyo chaiyo dhizaini uye machining ezvimbi uye machani inovimbisa yakanyanya nzvimbo yepamusoro yekutamisa kupisa, ine kushivirira kwakasimba se ± 0.05mm kusvika ± 0.1mm. Izvi zvinobatsira kuchengetedza yakanyanya tembiricha yekushanda yechigadzirwa, kudzivirira kupisa uye kukuvara kunogona kuitika.

■ Kusarudzwa kwezvinhu:Aluminium alloys anowanzo shandiswa nekuda kweakanakisa ekupisa conductivity uye huremu hunhu. Semuenzaniso, aluminium 6061 uye 6063 isarudzo dzakakurumbira. Mune zvimwe zviitiko, mhangura inogona zvakare kushandiswa kune yayo yakanyanya kupisa conductivity, kunyanya mune yakakwirira-simba maapplication. Kurapa kwepamusoro senge anodizing kunogona kuiswa kuwedzera kupisa kupisa uye kudzivirira kubva mukuora.

Chassis uye Enclosures

■ Basa:Iyo chassis uye yakavharirwa haingope dziviriro yemuviri yemukati memagetsi zvikamu asi zvakare inobatsira kune yakazara dhizaini uye ergonomics yechishandiso. Vanoda kunyatsogadzirwa kuti ive nechokwadi chakakodzera uye kuungana kwezvikamu zvese, nekushivirira kazhinji mukati me ± 0.1mm kusvika ± 0.3mm. Sarudzo yezvinhu uye kupera kunokanganisa kusimba kwechigadzirwa, aesthetics, uye electromagnetic interference (EMI) kudzivirira kugona.

■ Mafungiro eZvinhu:Zvishandiso zvakaita sealuminium alloys, simbi isina tsvina, uye mapurasitiki einjiniya anoshandiswa. Aluminium inopa chiyero chakanaka chesimba, uremu, uye machinability. Simbi isina simbi inopa yakawedzera kusimba uye EMI kudzivirira. Mapurasitiki einjiniya, akadai seABS (Acrylonitrile Butadiene Styrene) uye PC (Polycarbonate), anofarirwa nemutengo wakaderera, dhizaini inoshanduka, uye zvivakwa zvekudzivirira.

Precision Connectors uye Mounting Brackets

■Basa:Zvisungo uye mabhuraketi anokwirisa akakosha pakushanda kwakaringana uye kuungana kwezvinhu zvemagetsi. Precision machining inovimbisa kurongeka kwakaringana uye kubatana kwakachengeteka pakati pezvikamu zvakasiyana, semabhodhi edunhu, madhiraivha akaomarara, uye mapaneru ekuratidzira. Kushivirira kwezvibatanidza zvinogona kunge zvakangofanana ne ± 0.02mm kusvika ± 0.05mm kuvimbisa hukama hwakavimbika hwemagetsi nemuchina. Mabhuraketi ekumisikidza anofanirwa kunyatsogadzirwa kuti abate zvinhu zvakasimba.

■ Zvinhu uye Machina:Brass uye simbi isina tsvina inowanzoshandiswa kune zvibatanidza nekuda kwekuita kwavo kwakanaka uye kusagadzikana kwekuora. Pakukwirisa mabhuraketi, aruminiyamu alloys kana simbi inogona kushandiswa zvichienderana nezvinodiwa zvesimba. Maitiro epamberi ekugadzira senge micro-milling uye waya EDM (Electrical Discharge Machining) anowanzo shandiswa kuwana iyo inodiwa chaiyo uye yakaoma maumbirwo.

Kuvimbiswa Kwehutano uye Precision Machining Matanho

Hunhu Hwakanaka

■Isu takaita yakaomesesa yemhando yekudzora hurongwa kuti tive nechokwadi chemhando yepamusoro yezvigadzirwa zvedu zvemuchina zvekombuta uye indasitiri yemagetsi evatengi. Izvi zvinosanganisira zvakakwana zvinopinda zvekuongorora zvinhu kuti zvionekwe kunaka uye kutaurwa kwezvakagadzirwa. Munguva yekugadzira machining, in-process ongororo inoitwa pamatanho akawanda uchishandisa advanced metrology midziyo yakadai seyekuyeresa michina yekuyeresa (CMMs), optical profilometers, uye magetsi ekuyedza michina. Zvigadzirwa zvekupedzisira zvinotariswa zvakakwana zvemhando yekutarisa, zvinosanganisira dimensional kurongeka, kuyedzwa kwekushanda, uye yekuongorora zvizorwa, kusangana neyakaomesesa miitiro yemusika wemagetsi.

■ Pamusoro pezvo, tinoitisa bvunzo dzezvakatipoteredza uye dzekuvimbika senge tembiricha nehunyoro kubhasikoro, kuvhunduka uye kuyedza kuzunguza, kuti tive nechokwadi chekuti zvigadzirwa zvedu zvinokwanisa kumira nemamiriro ekushanda akaomarara uye mashandisirwo emidziyo yemagetsi.

Precision Machining Maitiro

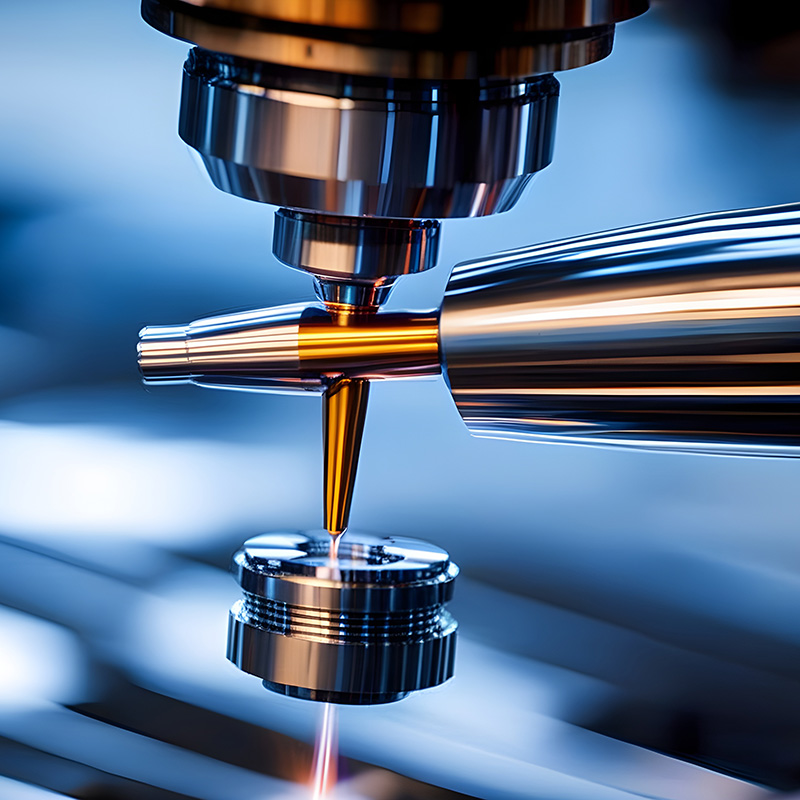

■ Mashandiro edu emuchina anoshandisa michina yechizvino-zvino yeCNC (Computer Numerical Control) ine masipidhi epamusoro-soro uye masisitimu ekushandisa epamusoro. Isu tinoshandisa akasiyana-siyana machining matekiniki, anosanganisira yakakwirira-kumhanya kugaya, kutenderedza, kukuya, uye kudhirowa chaiko, kuti tiwane kushivirira kwakasimba uye yakaoma geometries inodiwa kune zvemagetsi zvikamu.

■ Vagadziri vedu vane ruzivo uye mainjiniya vanoshanda pamwe chete nevagadziri vemagetsi kuti vagadzirise maitiro emuchina zvichienderana nedhizaini chaiyo uye kuita zvinodiwa zvechigadzirwa chimwe nechimwe. Izvi zvinosanganisira kugadzira zvigadziriso zvekushandisa uye zvigadziriso kuti ive nechokwadi chekugadzirwa kwakanaka uye kwakaringana.

Customization uye Dhizaini Tsigiro

Customization

■ Tinonzwisisa kuti indasitiri yekombiyuta nevatengi vemagetsi ine makwikwi makuru uye inogara ichishanduka, nevagadziri vachitsvaga zvinhu zvakasiyana uye zvakagadziridzwa kuti zvisiyanise zvigadzirwa zvavo. Naizvozvo, isu tinopa yakawedzera customization sarudzo dzezvigadzirwa zvedu zvemuchina. Kunyangwe iri tsika-yakagadzirwa sink yekudziya yechizvarwa chitsva chema processor, yakasarudzika yakavharika ine yakasarudzika fomu chinhu, kana chakanyatso kubatanidza chine isina-standard pini masisitimu, tinogona kushanda newe kugadzira nekugadzira mhinduro yakakwana.

■ Dhizaini yedu uye timu yeinjiniya inowanikwa kuti ibatane nemakambani emagetsi kubva padanho rekutanga repfungwa kusvika pakugadzirwa kwekupedzisira, ichipa ruzivo rwakakosha uye hunyanzvi hwekuita kuti kuve nechokwadi chekubatanidzwa kusina musono kwezvikamu zvemuchina mukugadzirwa kwechigadzirwa chose.

Dhizaini Tsigiro

■Pamusoro pekugadzirisa, tinopa masevhisi ekutsigira dhizaini kubatsira vagadziri vemagetsi kukwidziridza mashandiro uye kugadzirwa kwezvigadzirwa zvavo. Chikwata chedu chenyanzvi chinogona kubatsira mukusarudza zvinhu, dhizaini yekugadzira (DFM) kuongororwa, uye prototyping. Tichishandisa yepamusoro CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, tinogona kutevedzera machining maitiro uye kuona zvingangoitika zvekugadzira zvinhu zvisati zvagadzirwa, kuderedza nguva yekusimudzira uye mutengo uku tichiwedzera kunaka uye kuvimbika kwechigadzirwa chekupedzisira.

Mhedziso

COPYWRITER

Zvigadzirwa zvedu zvemuchina zvinopa iyo chaiyo, mhando, uye kugadzirisa inodiwa kune komputa nevatengi zvemagetsi indasitiri. Tine huwandu hwakawanda hwezvinhu uye machining kugona, isu tinokwanisa kupa mhinduro dzakavimbika dzekushandisa kwakasiyana-siyana, kubva pakupisa kupisa uye kugadzirwa kwechasisi kune zvibatanidza uye mabhuraketi anokwira. Kunyangwe iwe uchida imwe chete prototype kana yakakura-yakakura kugadzirwa, isu takazvipira kuendesa emhando yepamusoro michina yemuchina inosangana uye inodarika zvinotarisirwa nemusika wemagetsi.

Bata nesu nhasi kuti tikurukure komputa yako uye yevatengi zvemagetsi machining zvinodiwa uye rega tikubatsire kuunza mazano ako matsva muhupenyu.

Nguva yekutumira: Feb-15-2025