Nhanganyaya

Munyika yekutora mifananidzo, kunaka uye kuita kwemidziyo inotsamira zvakanyanya pazvinhu zvakanyatsogadzirwa nemuchina. Zvigadzirwa zvedu zvemuchina zvakashongedzwa zvine hungwaru kuti zvisangane nezvinodiwa chaizvo zveindasitiri yemifananidzo, kuwedzera kushanda, kusimba, uye iko kurongeka kwemhando dzakasiyana dzemifananidzo.

Key Machined Zvikamu uye Mashandisirwo Azvo

Kamera Muviri Zvikamu

■ Basa:Iyo kamera yemuviri ndiyo musimboti wechero midziyo yemifananidzo. Zvikamu zvakagadzirwa senge kamera chassis, lens mount, uye shutter mechanism yedzimba yakakosha pakushanda kwayo. Iyo chassis inopa yakagadzikana uye yakasimba chimiro, ichive nechokwadi chekuti zvese zvemukati zvikamu zvakanyatsoenderana. Iyo lens gomo, ine kushivirira kazhinji mukati me ± 0.02mm kusvika ± 0.05mm, inofanirwa kugadzirwa nehunyanzvi hwepamusoro kuti ive nechokwadi chekubatana kwakakwana uye kusina musono pakati pekamera nelenzi, kudzivirira chero kubuda kwechiedza kana kusarongeka kunogona kukanganisa kunaka kwemufananidzo. Imba yevhavha yevhavha inodzivirira yakapfava yevhavha zvikamu uye inobatsira mukushanda kwakatsetseka uye kwakaringana kwevhavha, iyo yakakosha pakutora mifananidzo yakapinza.

■ Kusarudzwa kwezvinhu:Zvishandiso zvakaita sealuminium alloys uye magnesium alloys zvinowanzo shandiswa kumitumbi yekamera. Aluminium alloys anopa chiyero chakanaka chesimba, uremu, uye mutengo, nepo magineziyamu alloys akareruka uye anopa hunhu hwakanyanya hwekunyorova, kuderedza mavhitaminzi anogona kudzima mifananidzo. Kune iyo lens gomo, simbi isina tsvina inowanzofarirwa nekuda kwesimba rayo rakakura uye kupfeka kuramba.

Lens Zvikamu

■ Basa:Malenzi maziso ekhamera, uye kurongeka kwawo kwakakosha zvakanyanya. Madhiramu emalens emuchina, mhete dzekutarisisa, uye mashizha ekuvhura ndizvo zvinhu zvakakosha. Iyo lens barrel inoda kugadzirwa ine kushivirira kwakasimba, kazhinji mukati me ± 0.05mm kusvika ± 0.1mm, kuve nechokwadi kurongeka kwakaringana kwezvinhu zvelens uye kupa yakatsetseka uye chaiyo zoom uye kutarisa kushanda. Mhete yekutarisa uye mablades ekuvhura anoda chaiyo machining kuti abvumire kugadziridzwa kwakaringana uye kwakatsetseka, zvichiita kuti vanotora mifananidzo vadzore kudzika kwemunda uye kunyatsotarisa pazvinhu zvavo.

■ Mafungiro eZvinhu:Pamadhiramu emalens, zvinhu zvakaita sealuminium alloys nendarira zvinoshandiswa. Aluminium alloys akareruka uye anogona kuve anodized kuti awedzere kusimba uye kubata zvirinani. Brass inopa yakanakisa machinability uye kugadzikana, iyo inobatsira yakakwirira-chaiyo optical zvikamu. Iwo malenzi maelensi pachawo anogadzirwa kubva akasiyana magirazi emaziso, ayo anogadzikwa uye akakwenenzverwa kune akanyanya kunaka kushivirira kuti awane inodiwa yemaziso kuita.

Kuvimbiswa Kwehutano uye Precision Machining Matanho

Hunhu Hwakanaka

■ Takaisa hurongwa hwakazara hwekutonga kwemhando kuti tive nechokwadi chemhando yepamusoro yezvigadzirwa zvedu zvemichina zvemidziyo yekutora mifananidzo. Izvi zvinosanganisira kuomesera zvinhu zvinopinda zvekuongorora kuti zvionekwe mhando uye mataurirwo ezvakagadzirwa. Munguva yekugadzira machining, in-process yekuongorora inoitwa nguva nenguva uchishandisa advanced metrology midziyo yakadai seyekuyeresa michina yekuyeresa (CMMs), optical profilometers, uye interferometers. Zvigadzirwa zvekupedzisira zvinotariswa zvakaomesesa zvemhando, zvinosanganisira dimensional kurongeka kwechokwadi, optical performance test, uye durability kuyedzwa, kuti isangane neyakaomesesa miitiro yeindasitiri yemifananidzo.

■ Pamusoro pezvo, tinoita bvunzo dzezvakatipoteredza senge tembiricha nehunyoro kubhasikoro, kuvhunduka uye kuyedzwa kwekudengenyeka, kuti tive nechokwadi chekuti zvigadzirwa zvedu zvinokwanisa kumira nemamiriro ezvinhu akaomarara angasangana nevatori vemifananidzo mumunda.

Precision Machining Maitiro

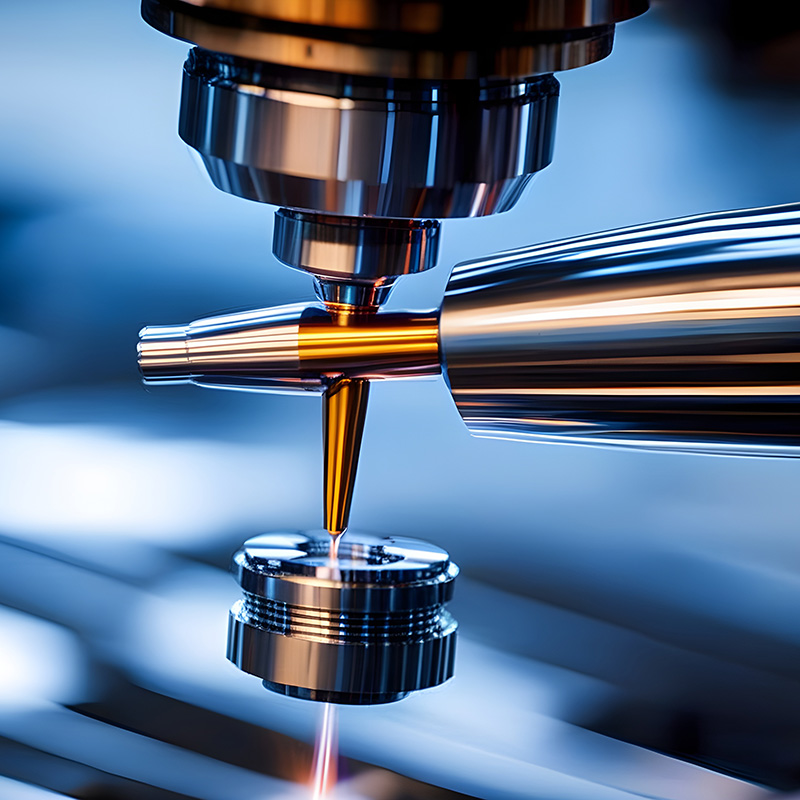

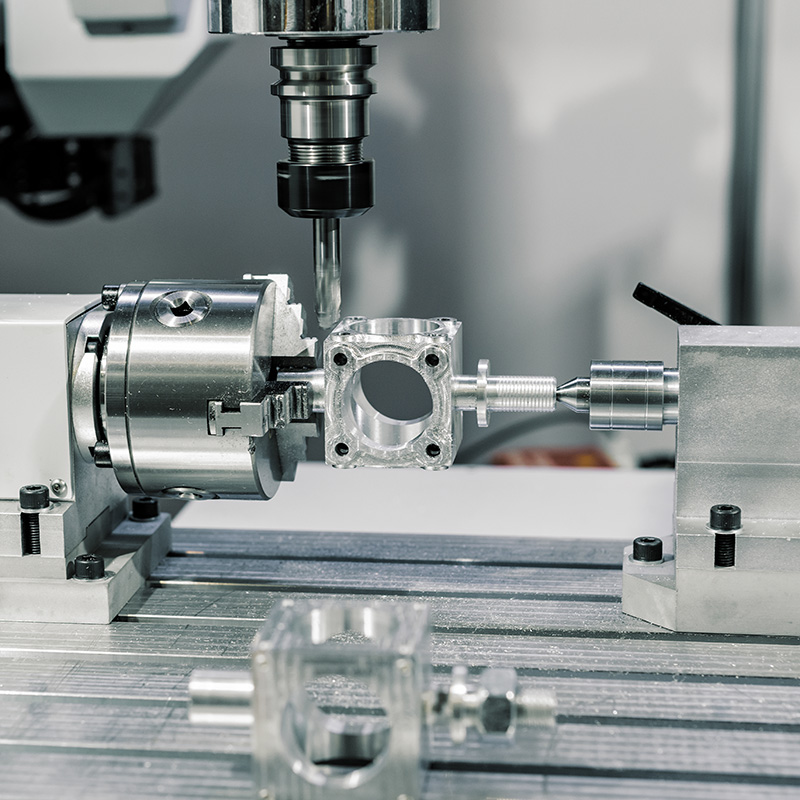

■ Mashandiro edu emuchina anoshandisa michina yechizvino-zvino yeCNC (Computer Numerical Control) ine masipidhi epamusoro-soro uye masisitimu ekushandisa epamusoro. Isu tinoshandisa akasiyana-siyana machining matekiniki, anosanganisira akakwira-kumhanya kugaya, kutendeuka, kukuya, uye kupeta, kuti tiwane kushivirira kwakasimba uye yakaoma geometries inodiwa pazvikamu zvekutora mafoto.

■ Vagadziri vedu vane ruzivo nemainjiniya vanoshanda pamwe chete nevagadziri vemidziyo yekutora mifananidzo kuti vagadzirise maitiro emuchina anoenderana nedhizaini uye kuita zvinodiwa zvechigadzirwa chimwe nechimwe. Izvi zvinosanganisira kugadzira zvigadziriso zvekushandisa uye zvigadziriso kuti ive nechokwadi chekugadzirwa kwakanaka uye kwakaringana.

Customization uye Dhizaini Tsigiro

Customization

■ Tinonzwisisa kuti vanotora mifananidzo nevagadziri vemidziyo vanowanzova nezvinodiwa zvakasiyana uye mazano ekugadzira. Naizvozvo, isu tinopa yakakura customization sarudzo dzezvigadzirwa zvedu zvemuchina. Ingave yakasarudzika-yakagadzirwa kamera kamera kune yakasarudzika mafoto maitiro kana yakasarudzika lenzi ine yakasarudzika yekuona maitiro, isu tinogona kushanda newe kuti chiono chako chive mhenyu. Isu tinokwanisa kugadzirisa saizi, chimiro, zvinhu, uye kupera kwezvikamu zvedu zvemuchina kuti zvizadzise zvaunoda chaizvo.

■ Dhizaini yedu uye timu yeinjiniya iripo kuti ibatane nemakambani ekutora mifananidzo kubva padanho rekutanga repfungwa kusvika pakugadzirwa kwekupedzisira, ichipa kukosha kwakakosha uye hunyanzvi hwekuita kuti kuve nechokwadi chekubatanidzwa kweseam kwezvikamu zvakagadzirwa mukugadzirwa kwemidziyo yese.

Dhizaini Tsigiro

■ Pamusoro pekugadzirisa, tinopa masevhisi ekutsigira dhizaini kubatsira vagadziri vemidziyo yemifananidzo kukwenenzvera kuita nekugadzirwa kwezvinhu zvavo. Chikwata chedu chenyanzvi chinogona kubatsira mukusarudza zvinhu, dhizaini yekugadzira (DFM) kuongororwa, uye prototyping. Tichishandisa yepamusoro CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, tinogona kutevedzera machining maitiro uye kuona zvingangoitika zvekugadzira zvinhu zvisati zvagadzirwa, kuderedza nguva yekusimudzira uye mutengo uku tichiwedzera kunaka uye kuvimbika kwechigadzirwa chekupedzisira.

Mhedziso

COPYWRITER

Zvigadzirwa zvedu zvemuchina zvinopa iyo chaiyo, mhando, uye kugadzirisa zvinodikanwa kuindasitiri yemidziyo yemifananidzo. Tine huwandu hwakawanda hwezvinhu uye kugona kugadzira, isu tinokwanisa kupa mhinduro dzakavimbika kune dzakasiyana siyana maapplication, kubva kumitumbi yekamera kusvika kune lenzi. Kunyangwe iwe uchida imwe chete prototype kana yakakura-yakakura kugadzirwa, isu takazvipira kuendesa emhando yepamusoro michina yemuchina inosangana uye inodarika zvinotarisirwa nemusika wekutora mifananidzo.

Bata nesu nhasi kuti tikurukure ako machining emidziyo yekutora mifananidzo uye rega tikubatsire kutora pfuti yakakwana nezvinhu zvedu zvakagadziridzwa-engineered.

Nguva yekutumira: Feb-15-2025